Herbert Machine Tools

Machine Tool Building, Reconditioning, Servicing and Repair

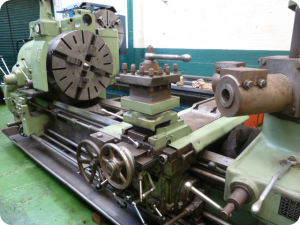

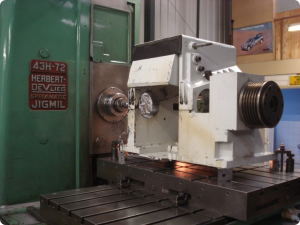

Rebuilt/Reconditioned machines

Our engineers at Herbert Machine Tools have over 40 years of experience in reconditioning and rebuilding all types of capstan/turret lathes , horizontal jig borers and vertical turning lathes and are familiar with almost every make and model of pedigree class machine tool that was ever built.

We never compromise on quality as we always use the best products available and work to exacting tolerances during our rebuilding process, as it is our aim to meet the crucial production deadlines for every job we undertake and offer all the advantages of quality working practices at realistic prices.

Our impressive client database consists of many ‘blue chip’ companies who have all benefited from our business associations with them.

Machine Service and maintenance support

Our machine service department is structured to offer our customers total pro-active support, coupled with a fast response to address on-site repairs.

In conjunction, we encourage our customers to consider opening a preventative maintenance service contract, to enable us to keep your machines in the best possible condition and remove the stress of unnecessary breakdowns that often lead even more costly production downtime.

Machine repair service

We cater for other types service work on-site where sub-assemblies can be removed and returned to our works for repair or refurbishment Including:

- Front Saddle Assemblies

- Cross slide & Apron Assemblies

- Turret Slide/Toolpost & Hexagonal Turret Assemblies

- Headstock, Gearbox & Transmission Assemblies

- Ballscrew & Leadscrew Assemblies Dressing

Typical Machine Types

- Herbert

- Ward

- Colchester

- Harrison

- Dean Smith & Grace

- Smart & Brown

- Holbrook

- Edgewick

- Webster & Bennett

- Devlieg

- Kearns Richards